PIPELINE INSPECTION TECHNOLOGY

Advanced Solutions for Pipeline Integrity

Precision-engineered tools for a safe and clean environment.

Who We Are

Precision Pipeline Inspection Through Innovation

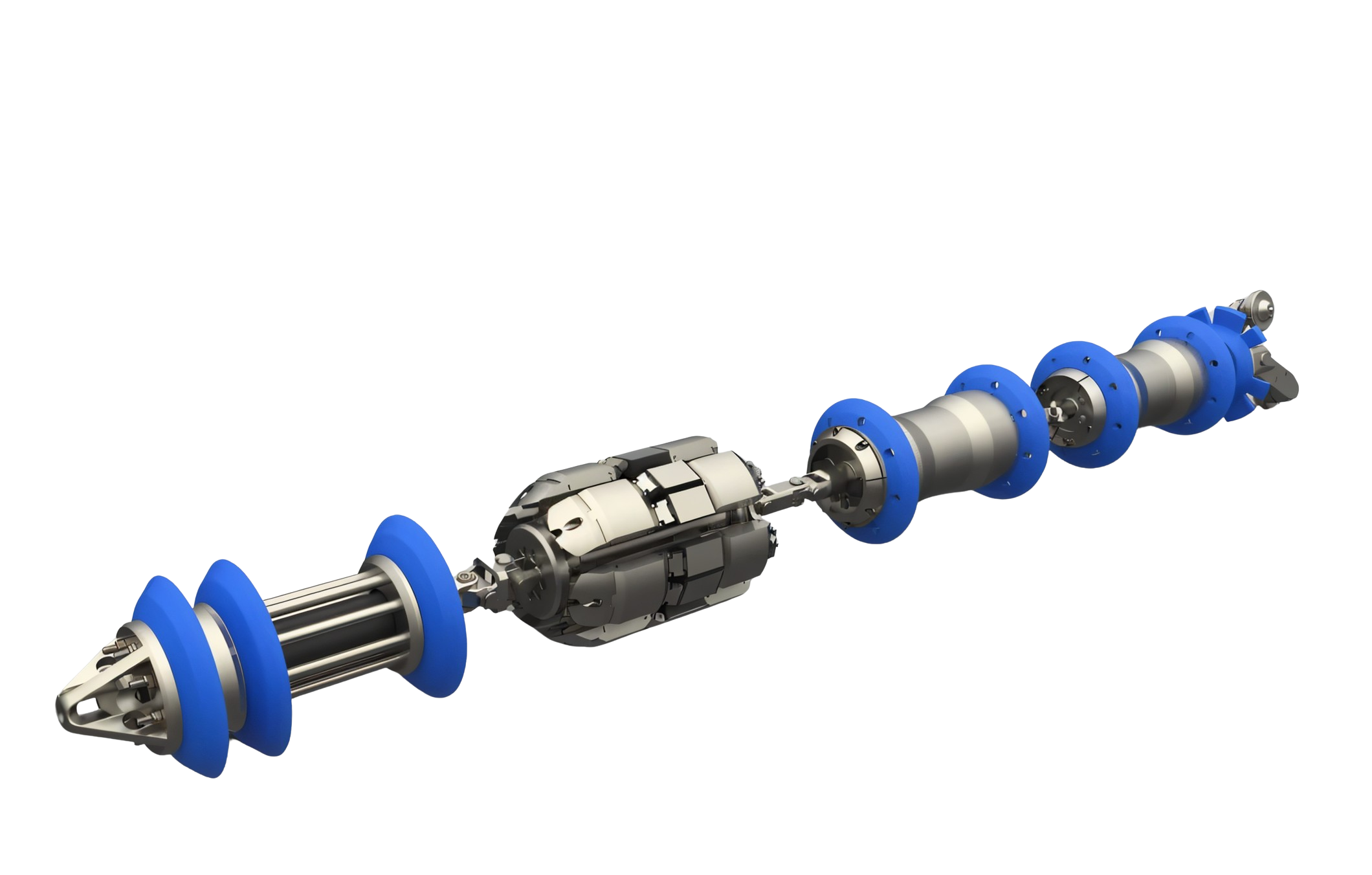

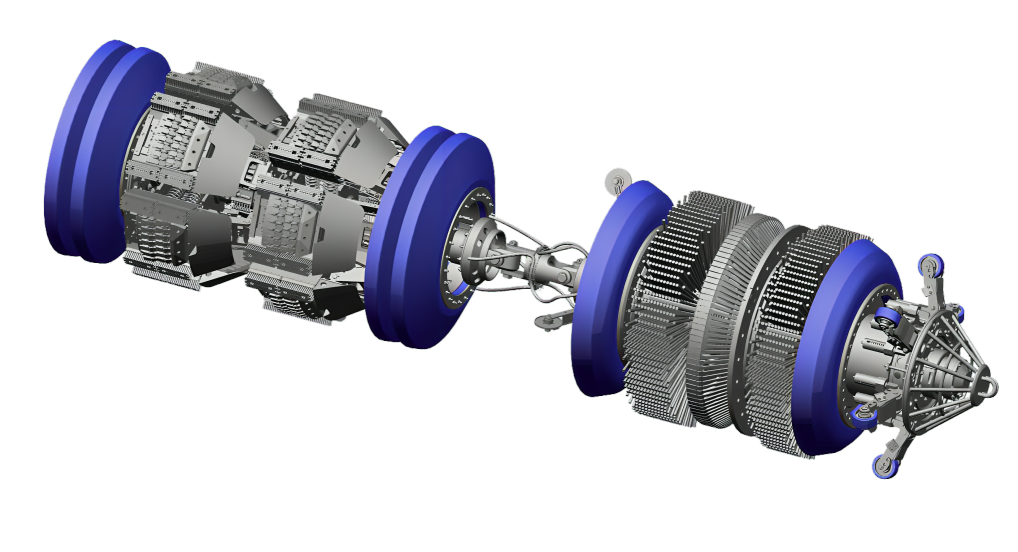

PipeScan is a pioneer in inline inspection (ILI) technology, delivering cutting-edge MFL, caliper, and cleaning pigging tools engineered for accuracy, durability, and unmatched performance. Our solutions empower the oil & gas, water, and industrial sectors to detect flaws, prevent leaks, and optimize pipeline integrity with data-driven precision.

PRECISION ENGINEERING

Advanced Pipeline Inspection Technology

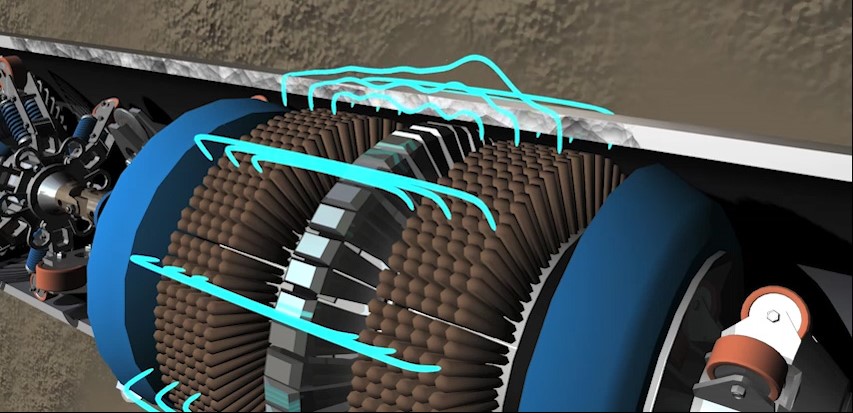

- 360° defect characterization with our proprietary multi-axis MFL technology

- Custom solutions for pipelines from 3" to 48" diameters

- Unmatched sizing accuracy as per POF

ADVANCED DIAGNOSTICS

Precision Pipeline Integrity Analysis

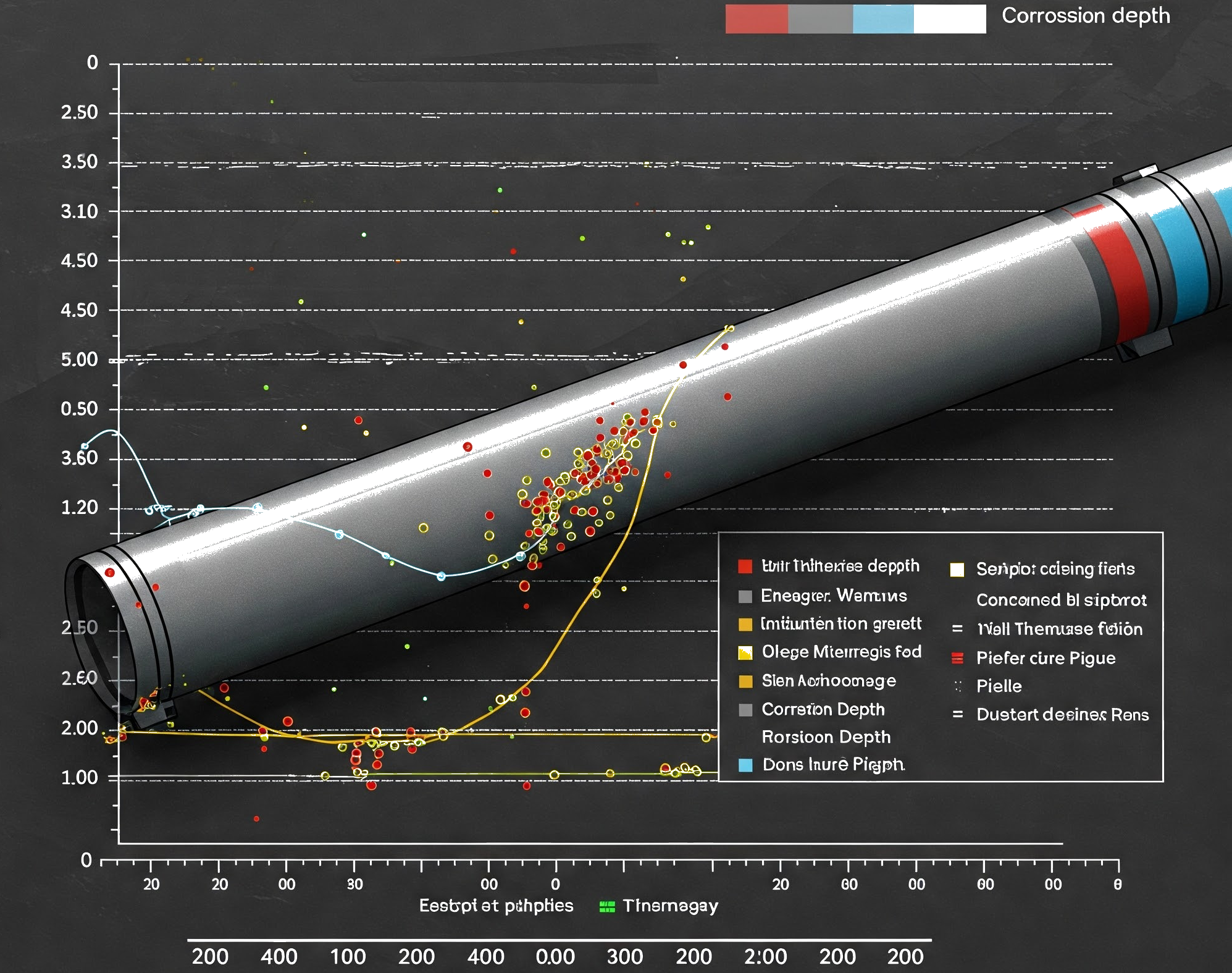

Our proprietary analysis platform transforms raw inspection data into actionable insights for pipeline integrity management. Leveraging advanced signal processing and machine learning algorithms, we deliver:

MFL Signal Interpretation

Advanced analysis for measuring corrosion and metal loss characteristics

Caliper Analysis

Precise measurement of dents, ovality, and deformations

Integrity Risk Assessment

API 1163-compliant evaluation of defect severity and remaining service life calculations

INDUSTRY INSIGHTS

Why Pipeline Inspection Matters

Our Locations

India & Far East

PipeScan Integrity Services Pvt Ltd.

Middle East & Africa

PipeScan Integrity Services, FZE

Operational Excellence

End-to-end pipeline inspection execution with precision

Efficient Preparation

- Pre-inspection tool calibration

- Site-specific configuration

- Comprehensive safety checks

- Client approval protocols

Effective Launching Procedure

- Standardized launch procedures

- Real-time monitoring setup

- Velocity control systems

- Emergency response readiness

Safe Receiving Procedure

- Controlled deceleration

- Immediate data backup

- Post-run integrity checks

- Preliminary findings report