Fully Integrated R&D Facility

Workshop Facility

Prototyping and tool assembly with precision machining capabilities

Project Management Office

Central hub for inspection project planning and execution

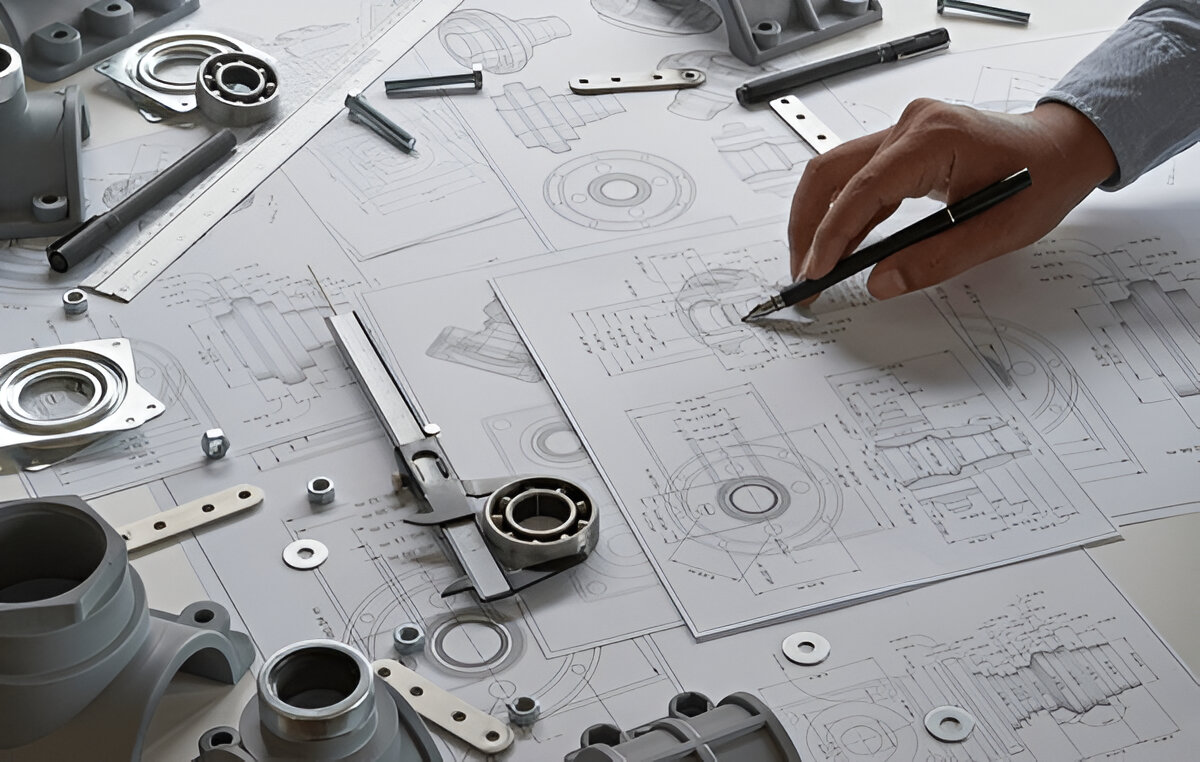

Mechanical Design

CAD/CAM development of inspection tools and components

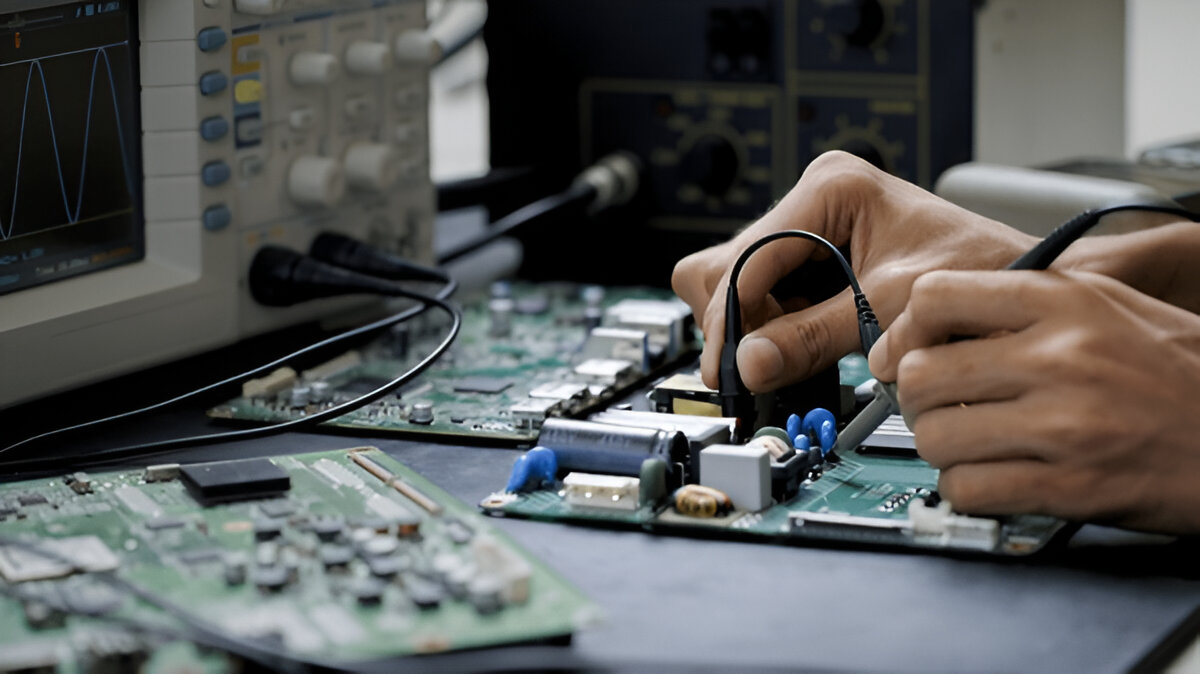

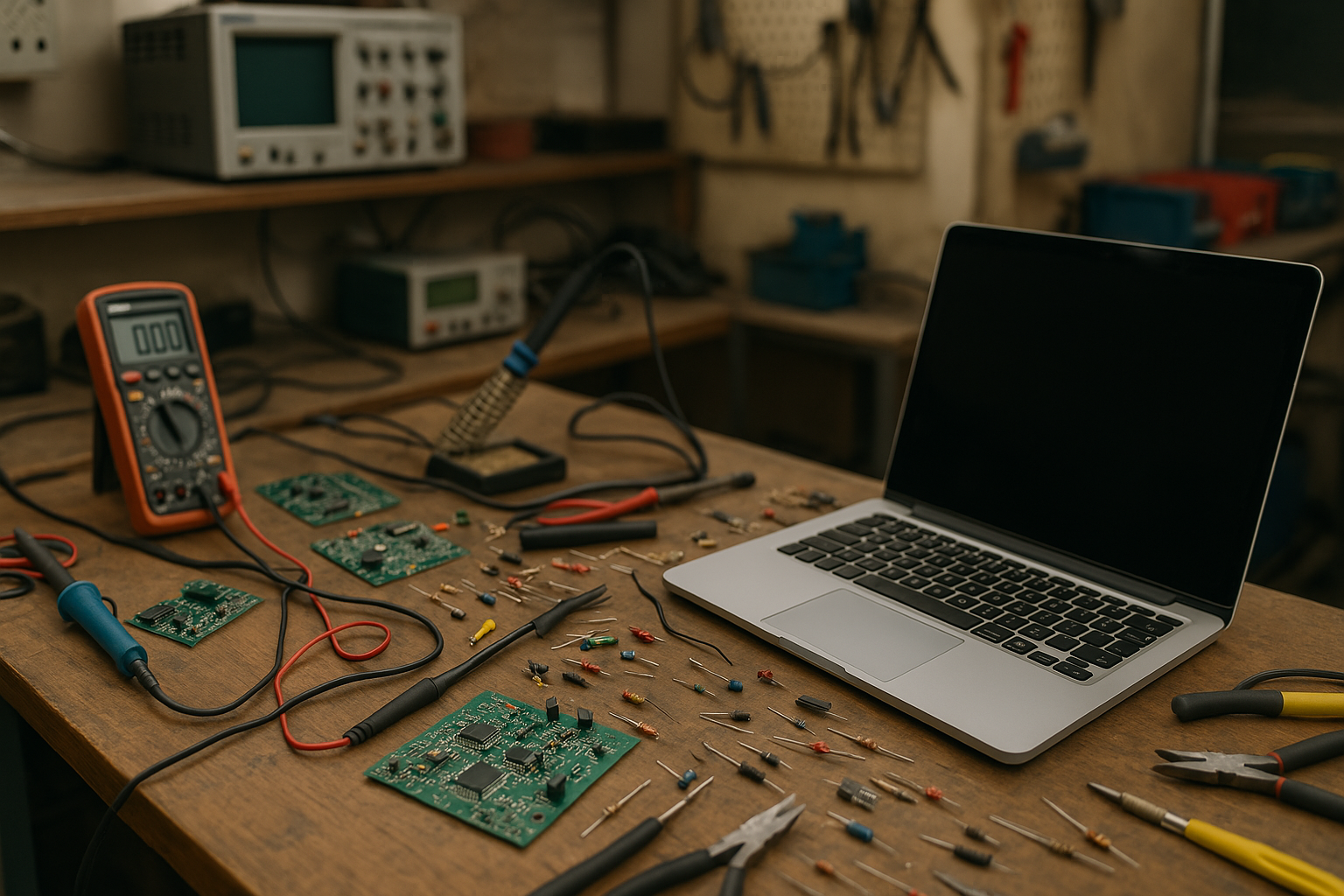

Electronics Lab

Specialized sensor development and advanced signal processing research

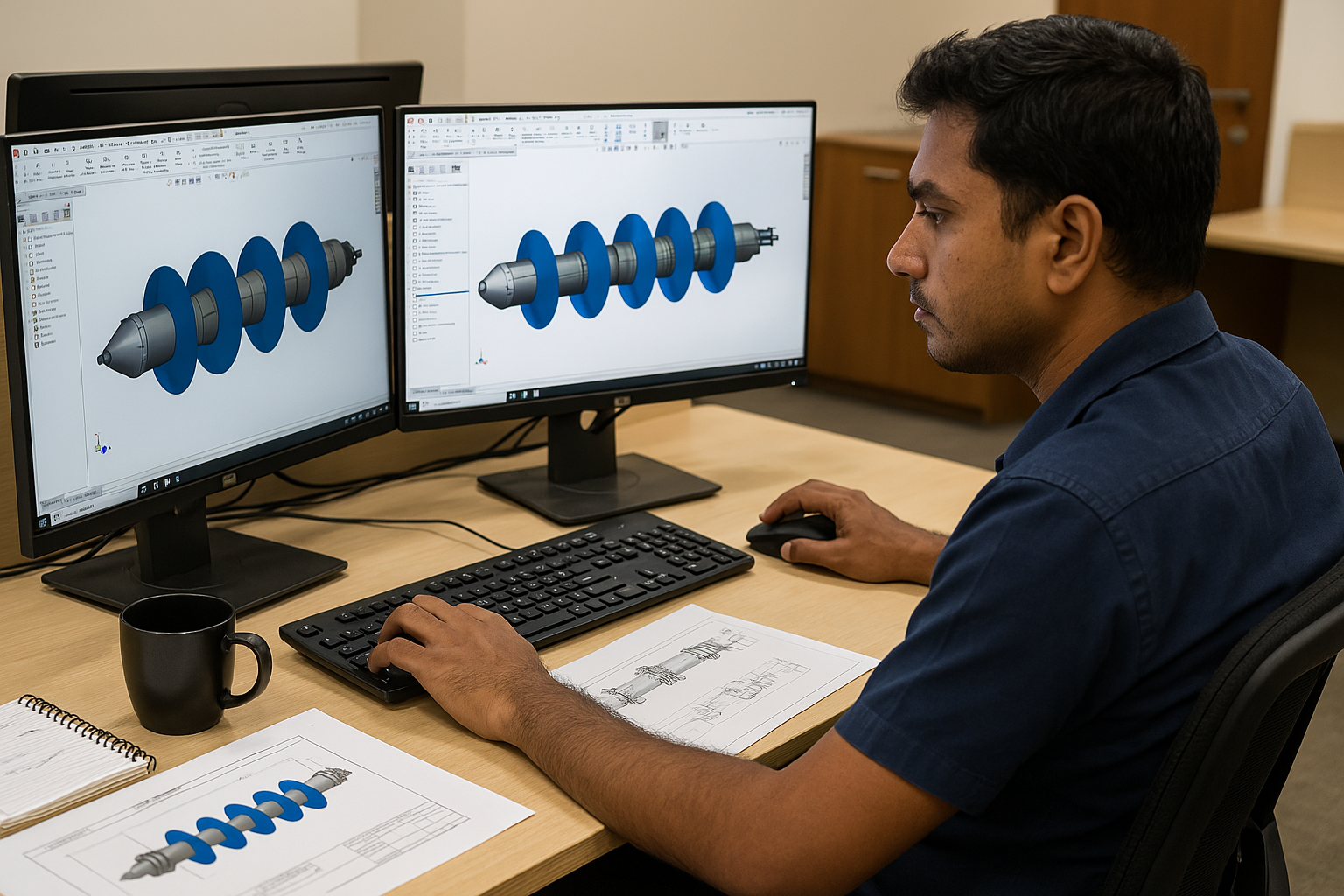

Software Department

Advanced algorithms for defect detection & 3D pipeline visualization

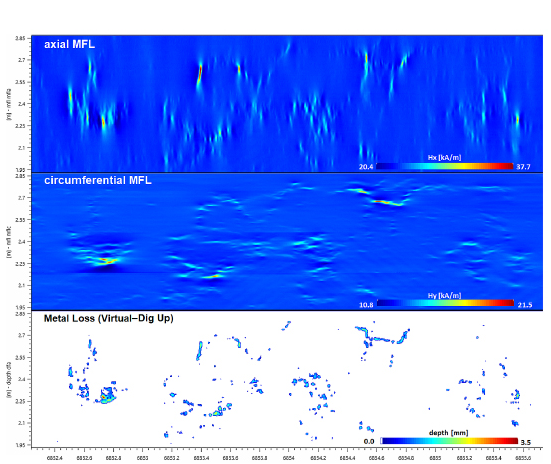

Data Analysis

Transforming raw inspection data into actionable integrity insights

Our R&D Team Structure

Specialized departments driving innovation in inspection technology

Tool Design

- CAD modeling & simulation

- Material selection

- Prototyping

- Ergonomics optimization

Electronics Development

- Sensor integration

- Signal conditioning

- Embedded systems

- PCB design

Tool Assembly & Testing

- Precision assembly

- Functional testing

- Environmental stress tests

- Calibration

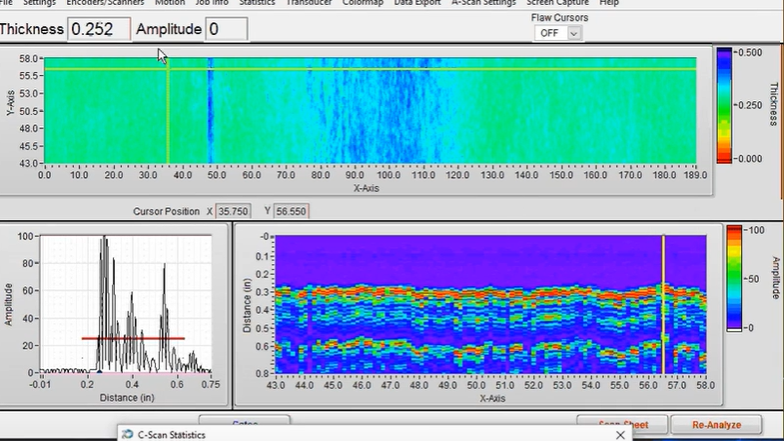

Data Analysis

- Algorithm development

- Statistical validation

- AI/ML integration

- Reporting automation

Our cross-functional teams collaborate through agile development cycles, ensuring seamless integration from concept to field deployment. Each project benefits from all four departmental expertise at every stage.

In-House Pull Test & Loop Test Capabilities

Rigorous validation protocols for inspection tool reliability

Loop Test Facility

Full-scale pipeline simulation for continuous tool validation under controlled conditions

MFL Pull Test

Precision defect characterization through controlled pull-through testing